After many years, I have decided to start doing DIY electronics again. Things have changed a great deal. Let me share my research here to save you some time if you are thinking about starting electronics DIY. What tools do you need, and what are some of the fun things you can do. But first, let me give you some background.

Background

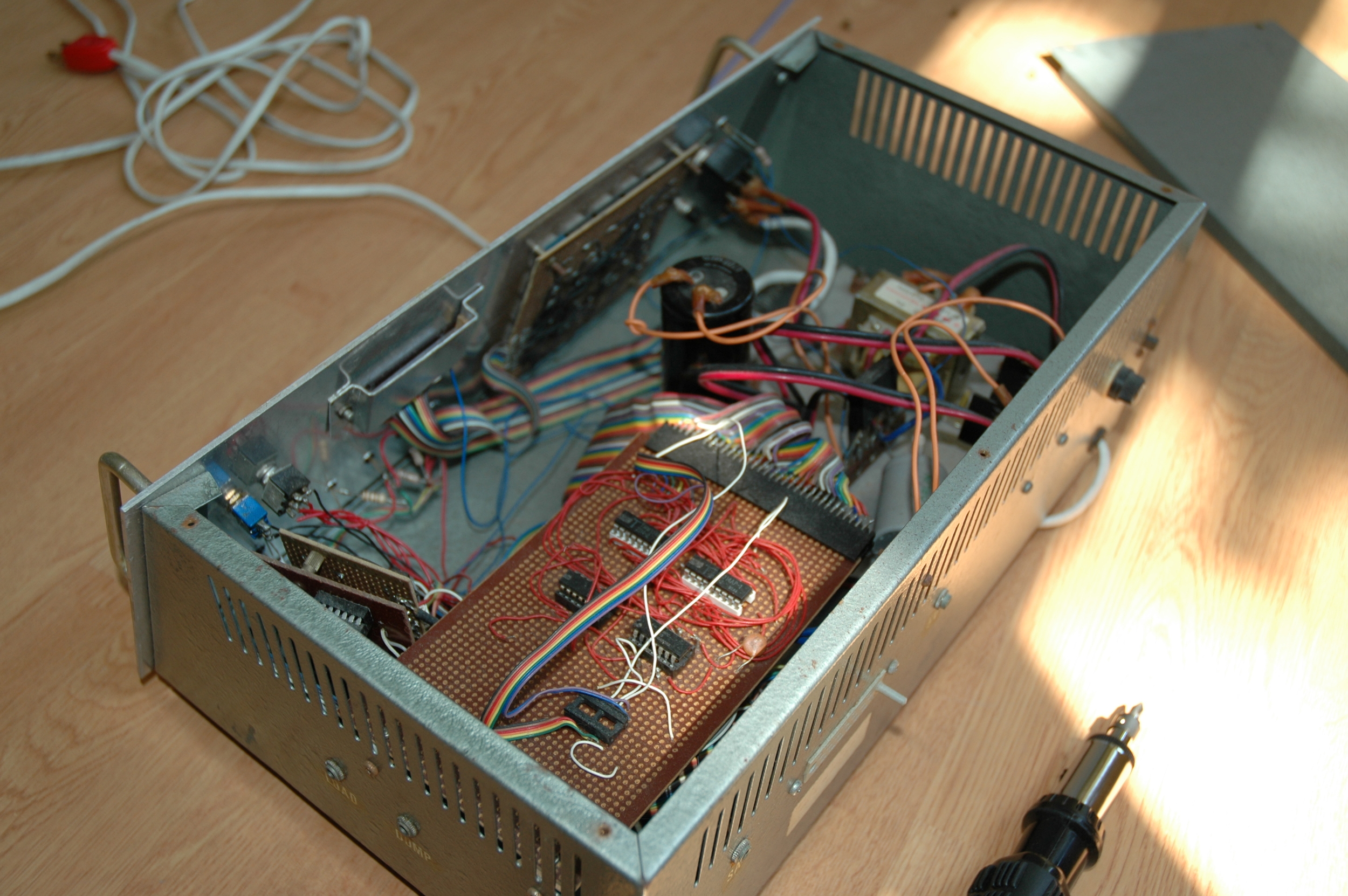

I am (was) a experience electronics circuit builder. I started when I was 11 or 12, building simple circuitry from electronic magazine. I built a micro-computer kit when I was in high school, sometimes hand wire (point-to-point) IC circuits together. I built an electronic recording keyboard as a CompSci thesis project from scratch. i.e. the operating system written in assembler, wire wrapped the entire system from discrete components interfacing with a 6800 microprocessor. Sound generation via a 890x sound generator chip. In other words, I spent months and probably thousands of dollars building something that you can now, 20 odd years later, buy from Target for $100. So I am skilled (stlll I hope) at soldering small PCB's in thru-hole mode, in reading schematics, and basic have understanding of basic electronic systems.

What I want to do now is to work in two different areas. Building audio components like headphone amplifiers and related devices, and build micro contoller based toys and devices, using the Arduino platform as a starting point. So my needs are mostly to building low power (except when I get to Tube amps) small scale electronics.

So, on to the tools:

Soldering Station

I am looking, borrowing a term from the camera world, for a "prosumer" level product. While most people will agree that a $30 soldering iron will do for basic soldering, a nice temperature adjustable unit will give me more flexibility in working with different things. For example soldering surface mount component may need a lower temperature, while soldering connectors and cables may need a higher temperature. A good soldering station also have faster heat-up and recover time, to make the work faster and more enjoyable. Finally, a good iron is lighter, with a more flexible cord, allowing for a more comfortable time.

There are two main brands out there -- Hakko, a Japanese brand, and Weller, an American brand owned by Cooper Hand Tools. Both brands offer two stations that fit the requirement. An analog dialed control station, and a dialed control with digital display station. For Hakko they are The Hakko 936 and the Hakko 937. For Weller they are the WESD51 and WES51.

The Hakko in general have better specs -- the temperature controls are +/- 1.8F, whereas the Wellers are +/- 9F. But with an analog dial to set the temperature, isn't the error rate too small to matter compare to the dial settings? Unless you use the digital display version. However, the price points goes like this, from cheapest to the most expensive: Hakko analog ~$80, Weller Analog ~$95, Weller Digital ~$130, Hakko Digital ~$200. Since there is no point in getting the Hakko, with the better temperature control, unless it is with a digital display, I decided to go with the Weller digital instead. It was around $130 if you search around online. Otherwise I would have bought the Hakko analog. I actually like the Hakko better, but the Weller seems to be more available in general here in the US.

Solder

I did not know this is such a complicated subject. When I was building stuff in school, I used whatever was in my Dad's tool box. Come to think of it, it must have been very old solder. I also had a tin of Rosin of some sort that I use. That's about it. Now I open a catalog and read all the tutorials, there are way too many things to choose from. RA, RMA, what core size, what solder size, 60/40 or 63/37 alloy, lead free, etc etc. I ended up with the standard Kester "44" 63/37 21 AWG .031 inch diameter 1 pound solder, Digikey part number KE1102-ND. I do not know yet how much flux cleaning I have to do right now, but I'll find out after the first project.

Desoldering Wick

I did not think I need this. I do. First soldering session -- soldering a female header on the protoshield. Got it a little off sided. Really could have used some desoldering wick. Instead I had to use the soldering tip to pull bits of solder off at a time trick. Not good for electronic components (too much heating).

Digital Multimeter (DMM)

Choosing a DMM is much harder. The "prosumer" version would be something from the US company Fluke. They are built well, with good feature, but very expensive. The basic model, the 115, will cost about $150. Then it goes up to the 177 model costing ~$220. The more professional model, the 77IV (version four, of a classic) cost close to $300.

Meanwhile, the Asian manufacturers have units as cheap as a few dollars, seriously. The big brand is Mastech which makes a lot of models, and also OEM for other companies. So you will see the same thing in sometimes different colors and names, but the model numbers will be similar. Another big brand is Extech. Choosing one of these cheap DMM is difficult because there are so many of them at every price point. The cheaper ones all seems to be of less quality in the physical sense. You may have problem with the buttons, the dial, etc. Seems like most of the $50 - $100 Asian unit will be adequate.

I couldn't bring myself to spending $200 on a Fluke DMM. I ended up getting an Extech EX330 for about $54. It has all the basic functions. The one "high end" feature that it does not have is "True RMS" measurements for AC.

Hand Tools -- wire cutter and pliers

There are too many to choose from. I ended up just going to Home Depot and picked up a $10 hobby tool set, a pair of crescent cutter and plier. It is small and works pretty well.

Hook Up Wires

References

I learnt a lot from these useful and popular references on these topic: